The action of confining within a defined space a microbiological agent or other entity that is being cultured, stored, manipulated, transported, or destroyed in order to prevent or limit its contact with people and/or the environment.”

At the same time, containment prevents dust, gases, or vapours from being released into the environment and contaminating the product.

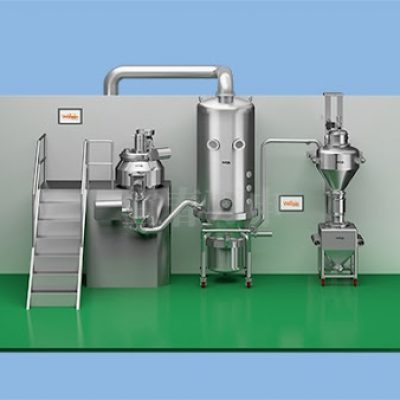

Isolator and containment systems are becoming increasingly important to the pharmaceutical industry.

Closed processes are not necessarily identical with a complete containment isolator. Depending on the potency of a substance, it might be sufficient to integrate a light or simple containment into the production process.

Examples of light containment include a double flap or a closed container where a closed line, hose or pipe transfers raw materials.

We at Flowtech we try to understand and evaluate the extent of containment as per the client’s requirement and suggest suitable containment solutions.

CONTAINMENT IS ACHIEVED BY BELOW TYPES

- USING SPLIT BUTTERFLY VALVE : Split Butterfly Valve (SBV), or containment valve, technology provides a safe method of transferring product from one container or process vessel to another whilst minimising the levels of dust emission to the operating environment before, during and after the material transfer.

- USING ISOLATOR : The pharmaceutical isolator is a bacteriologically sealed enclosure used in the medical and pharmaceutical environment for toxic processes and aseptic filling process. It also includes transfer systems that allow the entry and exit of the products and the elimination of waste without breaking aseptic conditions.

- RTP : Rapid Transfer Port (RTP) is a Double Door Transfer System. This system consists of two main components, the alpha flange and the beta assembly. The Alpha flange is normally mounted to the wall of a glovebox and the Beta assembly is mobile and connected to a container, bag, or process component. When the two assemblies are mated, hazardous materials can be rapidly transferred in and out of the glovebox without breaking containment, while maintaining the safety of the operators.

AVAILABLE RANGE – 5L – 1000L

Features

- Validation Compliant For Certification

- Customized Solution For User-Friendly Approach

- Compact Modules For Space.

- Integratable Units For Convineinece

- Cost Effective For Projects

- Better & Higher Yield For Good Results

- Automated Controls For Process Controls